SERVICES

Customer safety and asset integrity are our top priorities. We take this responsibility to heart, ensuring that our technicians are not only highly qualified and experienced but also passionately dedicated to achieving a near-zero incident rate.

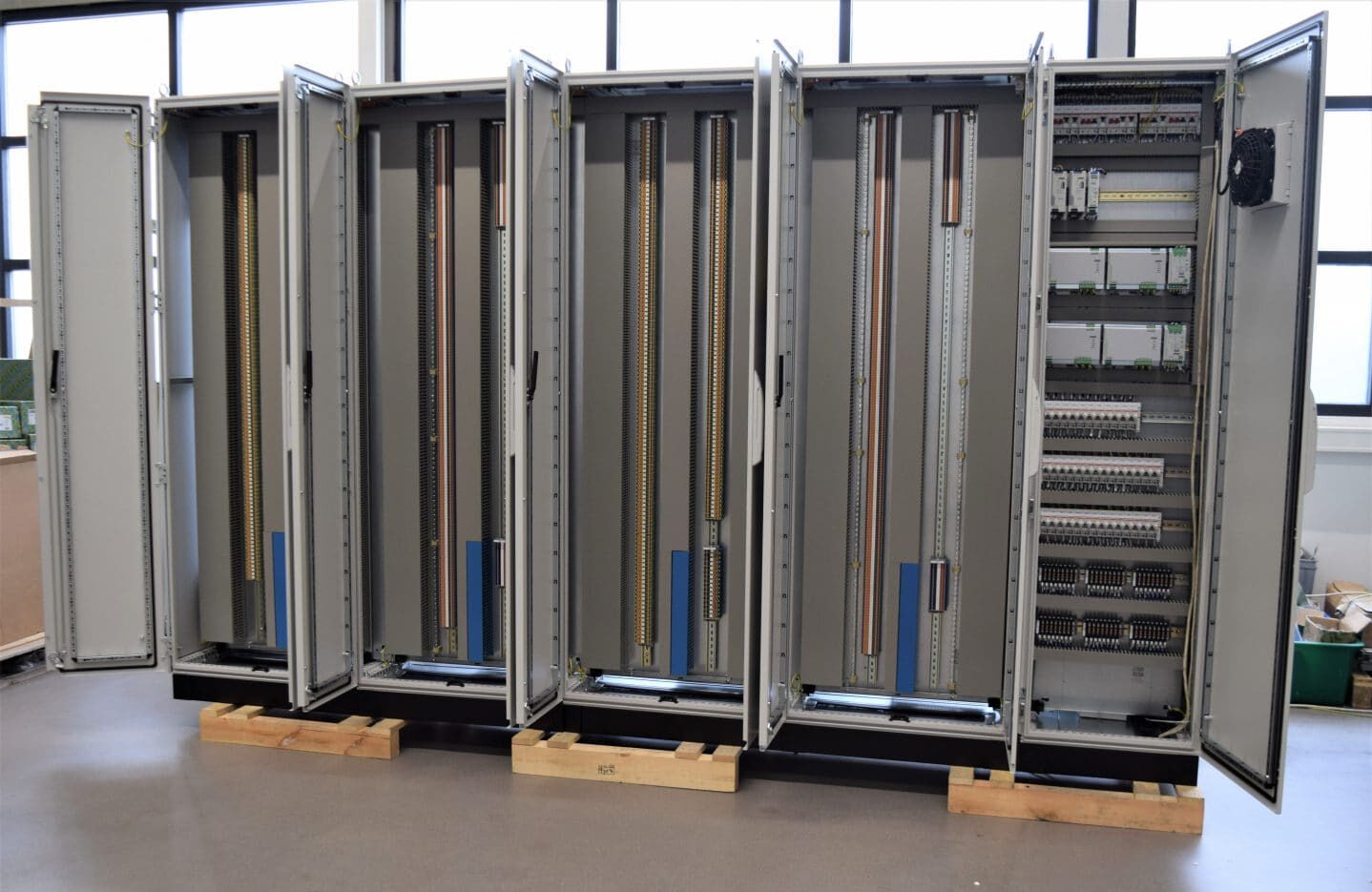

Control Cabinet Integration

Tightek specializes in delivering advanced and reliable Cabinet Integration Solutions, serving a wide range of industries including telecommunications, data centers, electrical systems, and industrial automation. With a commitment to

precision, quality, and innovation, Tightek has established itself as a trusted partner for customized cabinet integration projects

Controlled Bolt Torqueing

At Tightek, we provide controlled bolting services that guarantee safety and precision for joint assembly throughout plant construction, turnarounds, and maintenance. We’ll partner with you to determine the right scope of work for your project, ensuring every flange detail is carefully recorded for future reference.

No matter the project’s scale, our team of seasoned technicians, trained to meet the highest industry standards, will carry out every task with the utmost expertise, so you can be confident that the work will be completed efficiently and safely.

Bolt Tensioning

Hydraulic bolt tensioning works differently from traditional torque methods. Instead of applying torque to rotate the nut and generate bolt load, a tensioner grabs the exposed threads and pulls the bolt axially, stretching it. This action lifts the nut off the surface, allowing it to be rotated back to the flange with very little torque.

Key Benefits of Hydraulic Bolt Tensioning:

Improved stability and control during the process

Highly accurate for precise bolt tightening

Reduced torque requirements, leading to less stress on equipment

Minimized cross-talk between neighboring studs, ensuring even load distribution

Faster overall process – multiple bolts can be tensioned at the same time